Automatic Checkweigher with Inkjet Printer | Inline Weighing & Coding System SCI-4523L3

- group name

- Checkweigher Combination System

- Min Order

- 1 piece

- brand name

- SameGram

- model

- SCI-4523L3

- Nearest port for product export

- shenzhen

- Delivery clauses under the trade mode

- CIP

- Acceptable payment methods

- T/T, L/C, D/P D/A, MoneyGram, Credit Card, PayPal, Westem Union, Cash, Escrow

- update time

- Sun, 08 Mar 2026 00:10:49 GMT

Paramtents

Belt speed 20-60m/min

Weighting accuracy ±0.5-±1g

Weighting section size L 45mm*W 23mm

Applicable product size L≤350mm; W≤230mm

Packging & Delivery

-

Min Order1 piece

Briefing

SCI-4523L3 is an automatic checkweigher with an printer that can checkweigh and print serial numbers, batch numbers, QR codes, etc.

Detailed

Detail Information

Automatic Checkweigher with Inkjet Printer | Inline Weighing & Coding System SCI-4523L3

Introduction

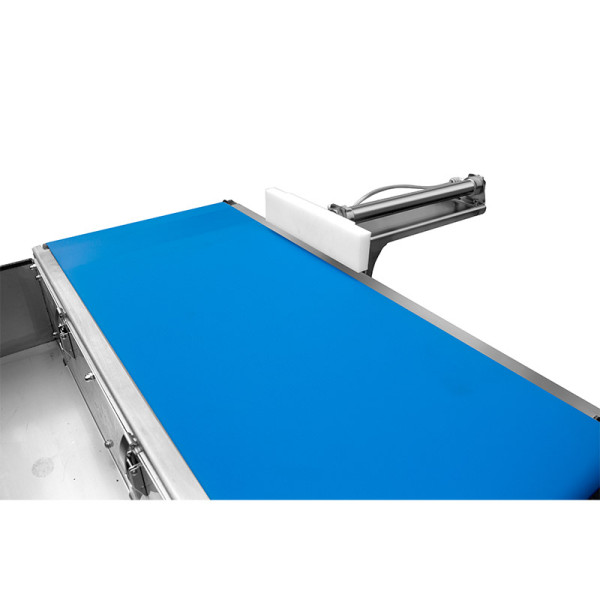

The automatic checkweigher with printer combines dynamic weighing and real-time inkjet coding in a single inline solution. It verifies product weight during post-packaging inspection and prints batch details, expiry dates, or traceability codes automatically, keeping production consistent and compliant.

Built for high-speed lines, the system helps reduce manual handling, improves coding accuracy, and maintains stable throughput. Its stainless-steel structure, clear interface, and reliable detection functions make it suitable for food, pharma, and other industries requiring precise quality control.

With features such as fast conveyor weighing, integrated inkjet printing, and flexible connectivity, it helps eliminate weight deviations, coding errors, and the inefficiencies of manual checks—delivering a more efficient and traceable packaging process.

Checkweigher with Inkjet printer Combination System SCI-4523L3

Features

Checkweigher with Inkjet printer Combination System SCI-4523L3 Technical Parameters

| Product model | SCI-4523L3 | |

| Weighting range | 1-3000g | |

Weighting section size | L 45mm*W 23mm | |

Air pressure interface | Φ8mm | |

| Case material | 304 stainless steel | |

Conveying direction | Facing the machine, left in and right out | |

Display division | 0.1g | |

| Weighting accuracy | ±0.5-±1g | |

| Applicable product size | L≤350mm; W≤230mm | |

Storage formula | 100 types | |

| Power supply | AC220V±10% | |

| Air source | 0.5-0.8MPa | |

Data transmission | USB data export | |

Alarm mode | Sound and light alarm and automatic rejection | |

| Optional function | Real-time printing, code reading and sorting, online code spraying, online code reading, online labeling | |

Operation screen | 10-inch Weiluntong color touch screen | |

Control system | Samegram online weighing control system V1.0.5 | |

| Other configurations | Meanwell power supply, Jingyan motor, Swiss PU food conveyor belt, NSK bearing, Mettler Toledo sensor | |

Available Rejection Systems for Checkweigher with Inkjet printer SCI-4523L3

Samegram’s Belt Drop rejector is a high speed rejector using pneumatic lift rods to gently remove thin bags and flat products.

Up and Out Rejector for checkweigher and metal detector systems — stable, gentle, and precise for soft or thick products.

Fast swing arm works with checkweigher or metal detector systems to remove defective boxes and bags up to 1 kg.

The heavy-duty pusher rejector pair with checkweigher systems to deliver accurate, mid-speed removal of heavy, boxed items.

* The maximum checkweighing speed and accuracy may vary depending on the actual product being tested and the installation environment.

* When selecting the model, pay attention to the direction of product movement on the conveyor belt. For transparent or semi-transparent products, please contact our company.

* When selecting the model, pay attention to the direction of product movement on the conveyor belt. For transparent or semi-transparent products, please contact our company.

File Downloads

For more product related parameter files, please contact us.

Why choose this Inline Checkweighing & Coding System?

Manufacturing Standards & Certifications

•CE Certified: Compliant with EU machinery and electrical safety standards, ensuring safe operation in food, pharmaceutical, and consumer goods production lines.

•ISO 9001 Quality Management System: All SCI series machines are produced under ISO-certified quality control processes, guaranteeing consistent build quality and traceable manufacturing.

Data & Compliance Transparency

•Automatic Weight Logging: Each product’s weight, pass/fail status, and coding/printing record is automatically saved.

•Data Export Capability: Easily export to CSV, Excel, or connect with ERP/MES/QC systems for traceability and audit purposes.

•Audit-Ready Reports: Supports internal and regulatory quality audits with full production traceability.

Support, After-Sales & Customization

•Custom Solutions: Conveyor length, width, speed, and print method (inkjet/laser) can be adapted to customer-specific production lines.

•Installation Guidance & Training: Engineers provide setup support and operator training to ensure smooth commissioning.

•Spare Parts & Maintenance Support: Long-term availability of spare parts and service guidance ensures minimal downtime.

•Technical Assistance & Remote Support: global support for troubleshooting and configuration help.

Checkweigher with Inkjet printer System Application Scenarios & Industries

Precise Coding and Weight Verification

Allows inline weighing with either inkjet or laser printing to apply product name, date, weight, batch number, serial number, or custom content.

Eliminates separate coding steps.

Examples:

Pharmaceuticals and Health Products: Ensures precise weight verification and prints mandatory batch and expiry codes for regulatory compliance.

Dairy Products and Eggs: Checks the net weight of packaged products and prints production dates and traceability information in real-time.

Diverse Package Handling

Automatically logs weight, pass/fail status, and printed information.

Supports quality audits and regulatory requirements.

Examples:

Printed Matters: Weighs items (e.g., magazines, brochures) to confirm page completeness and applies unique codes for tracking.

Consumer Electronics and Toys: Confirms final package weight to detect missing components and prints serial numbers for inventory management.

Boost Efficiency and Reduce Manual Work

Automated inline weighing, rejection of non-conforming packages, and real-time coding reduce labor and errors.

Example:

Confectionery, Snacks and Nuts: Verifies weight of snack bags/boxes to prevent under-filling and applies variable data like best-before dates.

Traceability and ComplianceDiverse Package Handling

Flexible integration and customizable printing/weighing parameters.

Suits various bags, boxes, pouches, or cartons.

Checkweigher with Inkjet printer System Application Cases

Checkweigher with Inkjet printer System FAQS

Q: What packaging types can this system handle?

A: Cartons, pouches, bags, boxes, cartons — as long as package dimensions and weight fall within the customized conveyor and checkweigher parameters.

Q: Can the inline printer handle printing of different data (batch code, date, weight, barcode, QR code)?

A: Yes. The integrated inkjet coding system supports printing batch/lot numbers, production dates, expiry dates, net weight, barcodes or QR codes as required.

Q: If a package fails the weight check, will it still be coded / labeled?

A: No. The system is configured to reject non-conforming packages — only “pass” packages proceed to the coding/labeling module.

Q: Is data export supported? Can I connect to ERP or quality‑control system?

A: Yes. The system logs weight inspection results and coding records, which can be exported (e.g. CSV / Excel) or connected to ERP / MES / QC systems for traceability and audit compliance.

Q: Can this system integrate with my existing filling / packaging / cartoning equipment?

A: Yes — the inline weighing + coding system is designed to integrate with upstream fillers, packers, cartoners, vertical packaging machines and downstream conveyors, enabling full automation of your packaging line.

Q: Is the machine suitable for food/pharma environment (hygienic, easy to clean)?

A: Yes. The system uses stainless‑steel and hygiene‑grade components, suitable for clean‑down / wash‑down conditions (depending on configuration), and designed for hygiene‑sensitive production.